EcoCut 3200

Automatic cutting machine for measuring and cutting round material. It can be equipped with either a tube cutting head or a universal cable cutting head. The tube cutting head can process tubing up to 12.7 mm O.D. with outstanding quality. The universal cable cutting head can process wire, cable and tubing up to 10 mm O.D. The EcoCut 3200 can be used as a stand alone machine or it can be integrated into a processing line.

Function

The EcoCut 3200 is electronically controlled and features several interfaces for peripheral components. The electrically driven rollers feed the material to the cutting unit. The cutting unit is electrically driven and position controlled.

Features

- Cutter heads can be changed in less than one minute

- High output rate due to double cut system

- Fast and very quiet transport unit

- Easy, menu guided operation and programming

- All-electric operation

Technical Specifications

| Attribute | Value |

| Max. Tube Outer Diameter | 12.7 mm (0.5”) [Tube Cutting Head] |

| Max. Cable Outer Diameter | 10 mm (0.39”) [Cable Cutting Head] |

| Max. Wire Size | Stranded Wire 6 mm2 (AWG 8) / Solid Wire 4 mm2 (AWG 12) |

| Max. Feed Rate | 3.20 m/s |

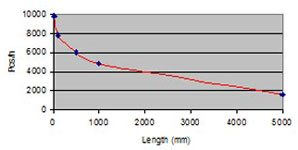

| Pulling Force | 50 N |

| Length Increments | 0.1 mm (0.004”) |

| Interfaces | Standard: Prefeeder, Hotstamp, RS232, Foot Pedal

Optional: Postfeed-Interface (CableCoiler 500), Inkjet-Interface |

| Options | Tube guides in 0.5mm increments from 2.0 – 13.0 mm. Custom tube guides, Custom blades Iguana TM Wire Processing software |

| Noise Level | <70 db (A) |

| Power Supply | 100 V, 115 V, 230 V or 240 V (50 – 60 Hz) |

| Dimensions (L × W × H) | 400 × 250 × 260 mm (15.7 x 9.8 x 10.2”) |

| Net Weight | 17 kg (38 lbs.) |

| Output Charge &

Repeat Accuracy |  up to 50mm +/- 0.3mm

50-200mm < 1%

200mm and larger < 0.5%

The values above are standard values,

variations are possible |

| CE-Conformity | The EcoCut 3200 fully complies with all CE and EMC equipment guidelines relative to

mechanical and electrical safety and electromagnetic compatibility. |

| Important Notice | Schleuniger recommends that wire / tube samples be submitted in cases where there

is doubt as to the processing capabilities of a particular machine. |